close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-07-11 Origin: Site

When venturing into the world of fasteners, one quickly realizes the sheer variety of nuts and bolts available. Each type serves a specific purpose, tailored to meet the demands of different applications. Among the most commonly used are hex nuts and Nyloc nuts. Both play crucial roles in construction, automotive, and machinery industries, but they are not interchangeable. Understanding the differences between these two can help ensure the integrity and safety of your projects.

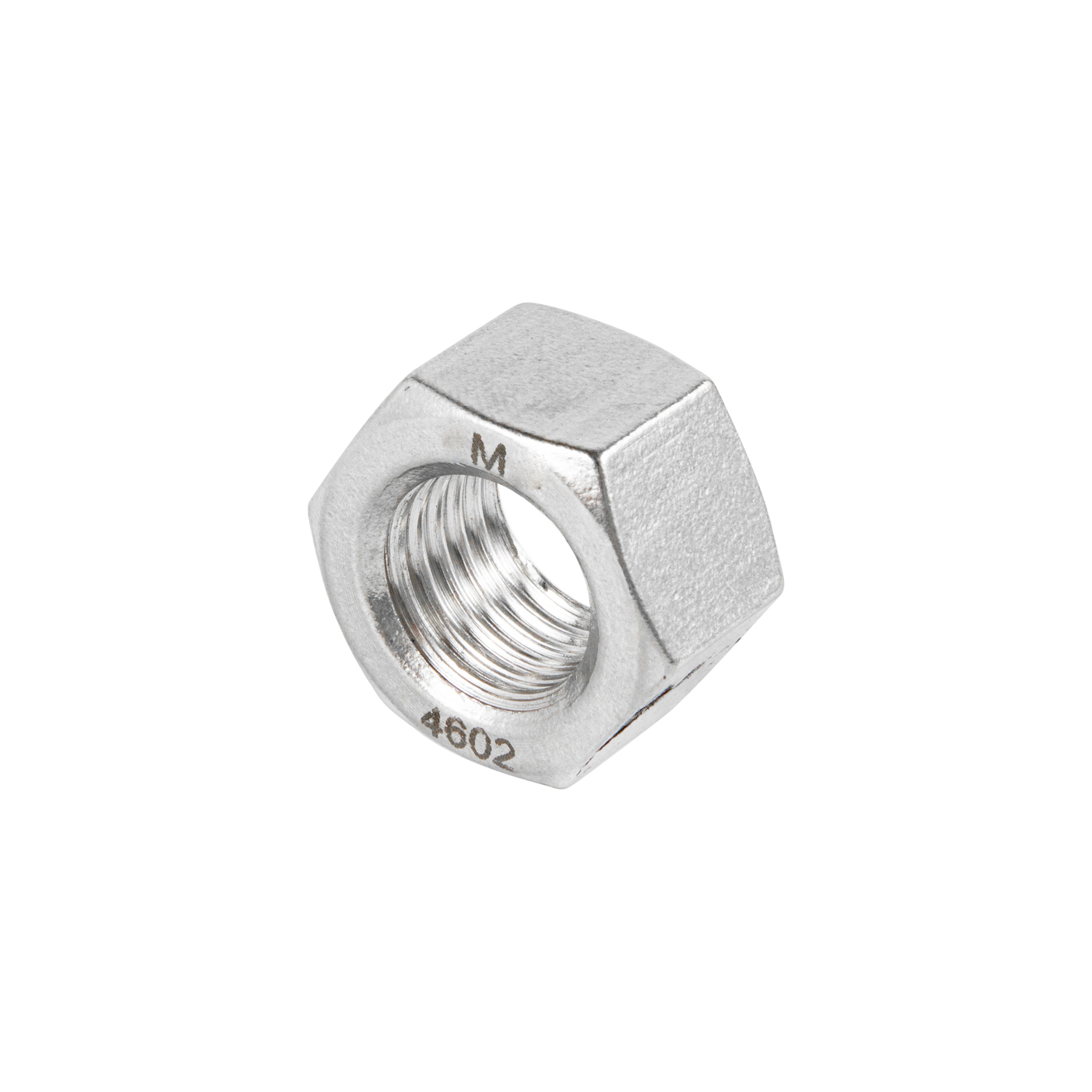

So, what sets a hex nut apart from a Nyloc nut? Essentially, the primary difference lies in their design and functionality: a hex nut is a standard six-sided nut used with bolts and screws, while a Nyloc nut is a type of lock nut with a nylon insert that prevents it from loosening.

Hex nuts are the quintessential fastening component found in numerous applications. Their six-sided shape makes them easy to grip from multiple angles using tools like wrenches and sockets. This design facilitates efficient tightening and loosening, which is essential in various assembly and disassembly tasks.

Typically made from steel, stainless steel, brass, or other metals, hex nuts are used in conjunction with bolts, screws, or threaded rods. They come in various sizes and thread pitches to accommodate different requirements. The simplicity of their design does not detract from their effectiveness; in fact, it enhances versatility.

In applications where vibration and movement are minimal, hex nuts provide a reliable fastening solution. They can be easily tightened to create a secure joint between components. However, in environments where vibrations are present, there is a risk that standard hex nuts may become loose over time if not properly secured.

To mitigate this issue, additional components like lock washers or thread-locking compounds are sometimes used with hex nuts. These additions help maintain tension and prevent the nut from backing off due to vibrations or dynamic loads.

Nyloc nuts, also known as nylon-insert lock nuts, are a type of locking nut that features a nylon collar insert within the threaded section. This nylon insert plays a critical role in the nut's locking capability. When the nut is threaded onto a bolt, the bolt's threads cut into the nylon insert, creating friction that resists loosening.

The primary advantage of Nyloc nuts is their ability to maintain a secure hold even in the presence of vibrations and dynamic loads. The nylon insert provides a constant pressure against the bolt threads, which prevents the nut from turning unintentionally. This makes Nyloc nuts ideal for applications in automotive, aerospace, and machinery industries, where movement and vibrations are common.

Nyloc nuts are available in various materials, including steel and stainless steel, often with different coatings for corrosion resistance. The nylon insert is typically resistant to temperature variations and chemicals, but it does have operational limitations, particularly at extreme temperatures.

One important consideration is that Nyloc nuts are generally not intended to be reused multiple times. Each time the nut is removed and reinstalled, the nylon insert loses some of its locking ability. Therefore, for critical applications, it's recommended to use a new Nyloc nut to ensure optimal performance.

The fundamental design difference between hex nuts and Nyloc nuts lies in the addition of the nylon insert in Nyloc nuts. This insert is housed at the top of the nut and is slightly smaller in diameter than the bolt it is intended to mate with. As a result, the bolt threads deform the nylon as it passes through, creating a tight grip.

Hex nuts, on the other hand, have a uniform internal thread throughout with no additional locking features. They rely solely on the tension applied during tightening to maintain their position.

In terms of materials, both hex nuts and Nyloc nuts can be made from similar base metals like steel or stainless steel. However, the presence of the nylon insert in Nyloc nuts introduces considerations regarding chemical compatibility and temperature resistance. The nylon material can degrade when exposed to certain chemicals or high temperatures, which may limit the environments where Nyloc nuts can be effectively used.

Additionally, the manufacturing process for Nyloc nuts is slightly more complex due to the insertion of the nylon collar. This added complexity often results in a higher cost compared to standard hex nuts.

Hex nuts are widely used in general-purpose applications where locking mechanisms are not a primary concern. They are suitable for:

Structural connections in construction

Assembly of machinery where disassembly may be required

Situations where additional locking methods are employed

Nyloc nuts are preferred in scenarios where vibrations or dynamic loads could cause a standard nut to loosen. Common applications include:

Automotive assemblies, such as engine components and suspension systems

Aerospace applications where safety and reliability are critical

Machinery subject to constant movement or oscillations

When selecting between the two, it's essential to consider the operational environment. If the assembly will experience significant vibrations or if maintaining torque is critical, a Nyloc nut may be the better choice. Conversely, if the application involves high temperatures or requires frequent disassembly, a hex nut with alternative locking methods might be more appropriate.

Hex Nuts:

Advantages:

Simple and versatile design

Easy to install and remove

Cost-effective

Suitable for a wide range of applications

Disadvantages:

Prone to loosening under vibrations

May require additional locking mechanisms

Nyloc Nuts:

Advantages:

Provides excellent resistance to loosening due to vibrations

Maintains torque over time

Eliminates the need for separate locking washers or compounds

Disadvantages:

Not suitable for high-temperature applications (nylon can melt or degrade)

Generally more expensive than standard hex nuts

Limited reusability due to nylon insert wear

Understanding these pros and cons is vital when selecting the appropriate nut for your project. It's not merely a matter of cost but also of safety, reliability, and performance over time.

In the realm of fastening components, both hex nuts and Nyloc nuts serve essential functions but cater to different needs. While hex nuts offer simplicity and versatility for general applications, Nyloc nuts provide enhanced security against loosening in environments subject to vibrations and dynamic forces.

By recognizing the key differences—particularly in design, functionality, and suitability for specific conditions—you can make informed decisions that enhance the integrity and longevity of your assemblies. Always consider factors such as environmental conditions, the necessity for reusability, and potential exposure to chemicals or extreme temperatures.

Ultimately, choosing between a hex nut and a Nyloc nut depends on the specific requirements of your project. Assessing these needs carefully will ensure that you select the most appropriate fastening solution, leading to safer and more reliable outcomes.

1. Can I use a Nyloc nut in high-temperature applications?

No, Nyloc nuts are not suitable for high-temperature applications because the nylon insert can degrade or melt, compromising the nut's locking ability.

2. Are hex nuts reusable?

Yes, hex nuts are generally reusable, provided they are not damaged during use. They do not have components that wear out from installation and removal.

3. How do I choose between a hex nut and a Nyloc nut?

Choose a Nyloc nut if your application involves vibrations or movement that could loosen a standard nut. Opt for a hex nut in stable environments or when frequent assembly and disassembly are required.

4. Can I use a Nyloc nut more than once?

While it's possible to reuse a Nyloc nut, it's not recommended for critical applications because the nylon insert wears with each use, reducing its locking effectiveness.

5. Do I need additional locking mechanisms with a Nyloc nut?

No, Nyloc nuts have a built-in locking feature due to the nylon insert, eliminating the need for additional locking washers or thread-locking compounds.